SEN SIGMA | Mission Statement

Our mission is to provide innovative and reliable sensing and quality control techniques for both welding industries and for additive manufacturing. We strive for high quality innovation by continuously pursuing scientific, engineering and operational excellence. We are committed to the highest standards of integrity to serve the interests of our customers.

OUR PRODUCT

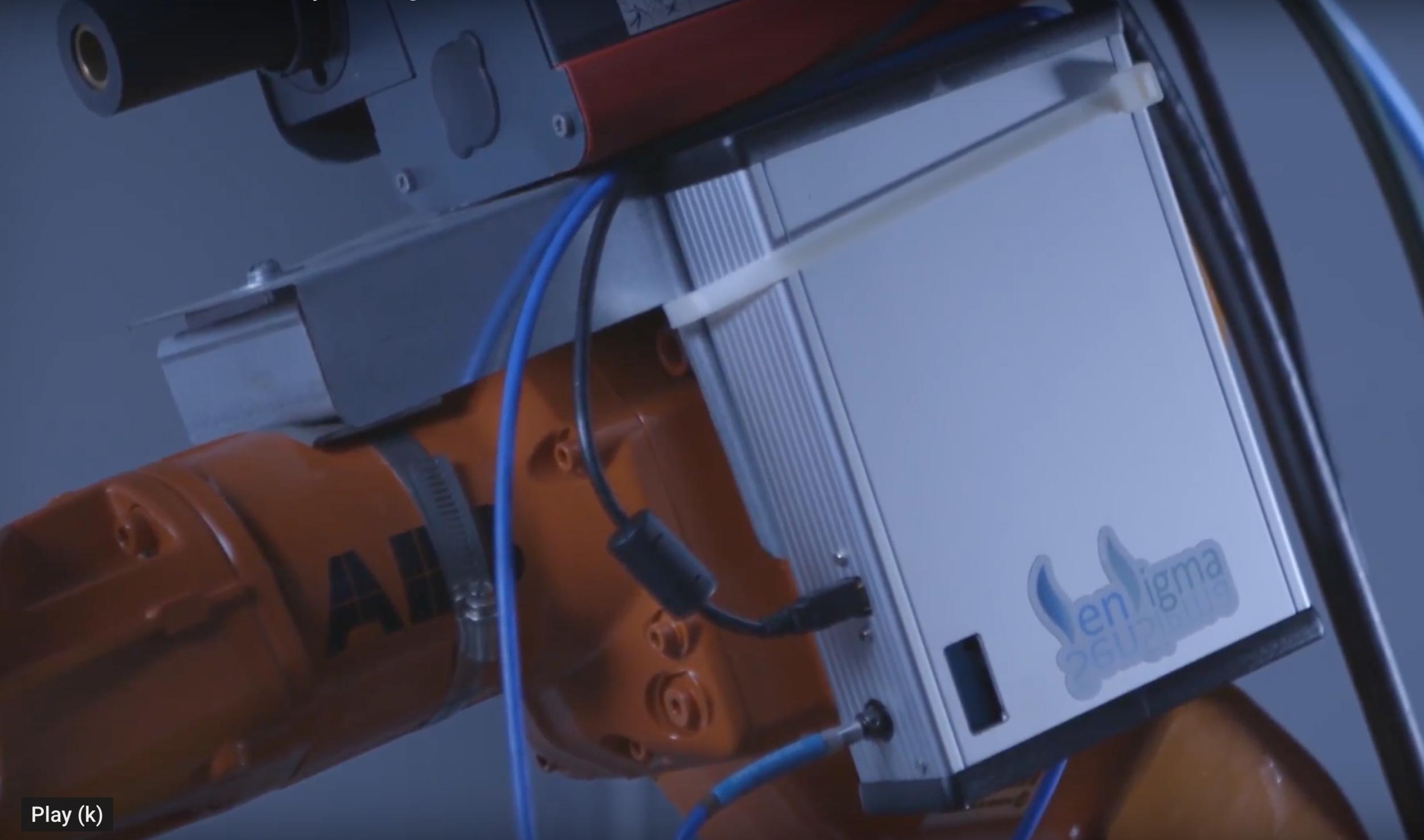

SenSigma focuses on an innovative technology to develop reliable, low-cost sensing and feedback system to maintain high quality, very low to no defect weld and additive manufacturing builds in various manufacturing processes. Our product is a Smart Optical Monitoring System (SOMS) suitable for any process generating plasma such as Electric Arc or Laser aided manufacturing process and utilizes spectroscopy and machine-learning software to ensure material integrity.

SenSigma benefits from research conducted at the University of Michigan and the talented workforce available in Ann Arbor, Michigan.

CUSTOMER FOCUS

Our focus is on the “unmet need” of our customers. The manufacturing industry in USA and the world ranging from arc and laser welding robot industry, material processing, energy and electricity, to automotive, heavy machinery, ship building and medical industry faces concerns such as material wastage, loss of valuable labor time and capital resource due to formation of defects during the manufacturing process.

Imagine Manufacturing with Sensor Technology

Defect Detection

Defect Categorization

In-situ monitoring of composition and phase transformation

Fast signal-processing capability

Insensitive to ambient disturbance

Data documentation for post-processing

Reduction in cycle time

High flexibility and sustainability for applications

TESTIMONIALS

“Having assessed SOMS(Smart Optical Monitoring System) as a technical expert in the laser material processing as well as advanced manufacturing field, I can say, it is a breakthrough technology for in-situ monitoring and control of phase transformation and composition by systematic diagnosis of the laser-induced plasma.”

“We at CoE-Welding - PSG College of Technology have been greatly impressed with the performance of the SenSigma LLC technology for In-situ monitoring of weld defects in GMAW process. We have integrated SOMS with a universal robot for automating the process for defect analysis. We have carried out trials by varying welding current, travel speed, gas flow rate and also by artificially creating defects. We are trying to use SOMS for SMAW electrode testing by automating the process.” ”

“We at Weld Mold have been highly impressed with the performance of the SenSigmaLLC technology in the ability to not only determine the chemistry in an active weld pool, but to be able to recognize potential defects such as non-metallic inclusions, slag coverage and porosity within the weld. The ability also to detect influences from materials not specifically placed in the manufacture of our material is also eye-opening.” ”

“I’m so glad that I have had a chance to use the Smart Optical Monitoring System (SOMS) by SenSigma LLC. It provides new possibilities for in-situ monitoring during various welding and deposition processes. It has made it possible for us to diagnose not only internal defects such as porosity but also external defects such as spatter and burn-through at reasonable cost. ”

LEARN MORE ABOUT SMART OPTICAL MONITORING SYSTEMS